PRODUCTS

EShop-number

Password

Welcome to CAIROX BELGIUM

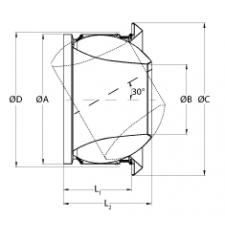

JET-GDA (RAL9006) • Grey design JET nozzle

Manually adjustable JET design nozzles

Finished in grey alu-look RAL 9006

Brand

- Cairox

Application

- JET nozzles are used for hot or cold air supply in ventilation and air conditioning systems where a long throw, high induction and low sound levels are required.

- The nozzles are manually adjustable to be set for cooling or heating purposes

Material

- Aluminium

Colour

- Standard colour grey (alu-look), RAL 9006

Composition

- The nozzle can be adjusted manually to direct the air flow over 30° in all directions.

Mounting

- Wall or rectangular duct mounting

- Cover flange to conseal mounting screws, removable by quarter turn.

- Mounting on the side of round ducts by means of a pipe branch and connection type ARG and MDV, or directly into the round duct

Text for tender

- The air supply diffusers are of the JET type for long throw application. They are made aluminium finished grey RAL 9006.

- ATC Type JET-GDA

Order example

- JET-GDA, 315

Explanation

JET-GDA = Diffuser type

315 = Connection diameter

Requesting information. Please wait a moment...