Swirl ceiling diffusers with high induction rate, consisting of a square plate with multiple fixed curved blades arranged in a circular pattern, to be equipped with galvanized steel plenum box

- VWR-FCSA, 600 + RER-B 600 + CRC 250

Explanation

VWR-FCSA = Diffuser type

600 = Diffuser size/swirl size

Accessories

RER-B = Plenum box type

600 = Size plenum box

CRC = Plenum box connection valve

250 = Plenum box connection diameter 250

Dimensions

|

| VWR-FCSA 300 | 238 | 86 | 236 | 296 | 41 | 16 | | VWR-FCSA 400 | 338 | 140 | 336 | 396 | 41 | 22 | | VWR-FCSA 500 | 438 | 170 | 436 | 496 | 41 | 24 | | VWR-FSCA 600 | 538 | 170 | 536 | 596 | 22 | 24 | | VWR-FSCA 625* | 538 | 170 | 536 | 621 | 22 | 24 | | * niet meer verkrijgbaar / n'est plus disponible / no longer available |

Quick selection

|

| Q | Ak | 0.023 | 0.03 | 0.0465 | 0.07 | 0.07 | |

| 100 | | H= | 2.7 | 0.17 | 0.13 | 0.11 | | | | | | | | | | | | | | Vz | H= | 3.2 | 0.14 | 0.11 | 0.09 | | | | | | | | | | | | | | | H= | 3.8 | 0.11 | 0.09 | 0.08 | | | | | | | | | | | | | | Vk | 1.2 | | | | | | X0,25 | 0.9 | | | | | | Ps | 7 | | | | | | Lw(A) | <20 | | | | | | 150 | | H= | 2.7 | 0.26 | 0.2 | 0.16 | 0.23 | 0.18 | 0.15 | | | | | | | | | | | Vz | H= | 3.2 | 0.2 | 0.17 | 0.14 | 0.18 | 0.15 | 0.13 | | | | | | | | | | | | H= | 3.8 | 0.17 | 0.14 | 0.12 | 0.15 | 0.13 | 0.12 | | | | | | | | | | | Vk | 1.8 | 1.4 | | | | | X0,25 | 1.6 | 1.3 | | | | | Ps | 17 | 5 | | | | | Lw(A) | 26 | <20 | | | | | 200 | | H= | 2.7 | 0.34 | 0.26 | 0.21 | 0.29 | 0.23 | 0.2 | 0.21 | 0.17 | 0.14 | | | | | | | | Vz | H= | 3.2 | 0.27 | 0.22 | 0.19 | 0.24 | 0.2 | 0.17 | 0.17 | 0.15 | 0.13 | | | | | | | | | H= | 3.8 | 0.22 | 0.19 | 0.16 | 0.2 | 0.17 | 0.15 | 0.15 | 0.13 | 0.12 | | | | | | | | Vk | 2.4 | 1.9 | 1.2 | | | | X0,25 | 2.2 | 1.9 | 1.1 | | | | Ps | 30 | 8 | 2 | | | | Lw(A) | 34 | <20 | <20 | | | | 250 | | H= | 2.7 | 0.43 | 0.33 | 0.27 | 0.36 | 0.29 | 0.24 | 0.25 | 0.2 | 0.17 | | | | | | | | Vz | H= | 3.2 | 0.34 | 0.28 | 0.23 | 0.3 | 0.25 | 0.21 | 0.21 | 0.18 | 0.16 | | | | | | | | | H= | 3.8 | 0.28 | 0.23 | 0.2 | 0.25 | 0.21 | 0.19 | 0.18 | 0.16 | 0.14 | | | | | | | | Vk | 3 | 2.3 | 1.5 | | | | X0,25 | 2.9 | 2.5 | 1.5 | | | | Ps | 47 | 13 | 3 | | | | Lw(A) | 41 | 24 | <20 | | | | 300 | | H= | 2.7 | 0.51 | 0.39 | 0.32 | 0.43 | 0.34 | 0.28 | 0.29 | 0.24 | 0.2 | 0.22 | 0.17 | 0.15 | 0.22 | 0.17 | 0.15 | | Vz | H= | 3.2 | 0.41 | 0.33 | 0.28 | 0.35 | 0.29 | 0.25 | 0.25 | 0.21 | 0.18 | 0.18 | 0.15 | 0.13 | 0.18 | 0.15 | 0.13 | | | H= | 3.8 | 0.33 | 0.28 | 0.24 | 0.29 | 0.25 | 0.22 | 0.21 | 0.18 | 0.17 | 0.15 | 0.13 | 0.12 | 0.15 | 0.13 | 0.12 | | Vk | 3.6 | 2.8 | 1.8 | 1.2 | 1.2 | | X0,25 | 3.7 | 3.2 | 1.9 | 1.2 | 1.2 | | Ps | 67 | 19 | 5 | 2 | 2 | | Lw(A) | 47 | 30 | <20 | <20 | <20 | | 400 | | H= | 2.7 | | | | 0.56 | 0.44 | 0.37 | 0.38 | 0.31 | 0.26 | 0.29 | 0.24 | 0.2 | 0.29 | 0.24 | 0.2 | | Vz | H= | 3.2 | | | | 0.46 | 0.38 | 0.33 | 0.32 | 0.27 | 0.24 | 0.24 | 0.2 | 0.18 | 0.24 | 0.2 | 0.18 | | | H= | 3.8 | | | | 0.38 | 0.33 | 0.29 | 0.27 | 0.24 | 0.21 | 0.2 | 0.18 | 0.16 | 0.2 | 0.18 | 0.16 | | Vk | | 3.7 | 2.4 | 1.6 | 1.6 | | X0,25 | | 4.7 | 2.9 | 1.9 | 1.9 | | Ps | | 33 | 9 | 4 | 4 | | Lw(A) | | 39 | 21 | <20 | <20 | | 500 | | H= | 2.7 | | | | 0.69 | 0.54 | 0.46 | 0.46 | 0.38 | 0.32 | 0.37 | 0.3 | 0.25 | 0.37 | 0.3 | 0.25 | | Vz | H= | 3.2 | | | | 0.56 | 0.47 | 0.41 | 0.39 | 0.33 | 0.29 | 0.31 | 0.26 | 0.22 | 0.31 | 0.26 | 0.22 | | | H= | 3.8 | | | | 0.47 | 0.41 | 0.36 | 0.33 | 0.29 | 0.26 | 0.26 | 0.22 | 0.2 | 0.26 | 0.22 | 0.2 | | Vk | | 4.6 | 3 | 2 | 2 | | X0,25 | | 6.4 | 4 | 2.7 | 2.7 | | Ps | | 51 | 14 | 6 | 6 | | Lw(A) | | 45 | 28 | <20 | <20 | | 600 | | H= | 2.7 | | | | | | | 0.54 | 0.44 | 0.38 | 0.45 | 0.36 | 0.3 | 0.45 | 0.36 | 0.3 | | Vz | H= | 3.2 | | | | | | | 0.45 | 0.39 | 0.34 | 0.37 | 0.31 | 0.27 | 0.37 | 0.31 | 0.27 | | | H= | 3.8 | | | | | | | 0.39 | 0.34 | 0.31 | 0.31 | 0.27 | 0.24 | 0.31 | 0.27 | 0.24 | | Vk | | | 3.6 | 2.4 | 2.4 | | X0,25 | | | 5.2 | 3.6 | 3.6 | | Ps | | | 20 | 9 | 9 | | Lw(A) | | | 34 | 23 | 23 | | 800 | | H= | 2.7 | | | | | | | 0.7 | 0.57 | 0.49 | 0.61 | 0.48 | 0.41 | 0.61 | 0.48 | 0.41 | | Vz | H= | 3.2 | | | | | | | 0.59 | 0.5 | 0.44 | 0.5 | 0.42 | 0.36 | 0.5 | 0.42 | 0.36 | | | H= | 3.8 | | | | | | | 0.5 | 0.44 | 0.39 | 0.42 | 0.36 | 0.33 | 0.42 | 0.36 | 0.33 | | Vk | | | 4.8 | 3.2 | 3.2 | | X0,25 | | | 7.9 | 5.6 | 5.6 | | Ps | | | 35 | 15 | 15 | | Lw(A) | | | 43 | 32 | 32 | | 1000 | | H= | 2.7 | | | | | | | | | | 0.76 | 0.61 | 0.52 | 0.76 | 0.61 | 0.52 | | Vz | H= | 3.2 | | | | | | | | | | 0.63 | 0.53 | 0.46 | 0.63 | 0.53 | 0.46 | | | H= | 3.8 | | | | | | | | | | 0.53 | 0.46 | 0.41 | 0.53 | 0.46 | 0.41 | | Vk | | | | 4 | 4 | | X0,25 | | | | 8 | 8 | | Ps | | | | 24 | 24 | | Lw(A) | | | | 39 | 39 |

Symbols and specifications

- Q = Air Volume in m³/h

- Ak = Effective surface (free area) in m²

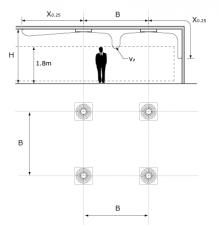

- B = Distance between diffusers in m

- H = Installation height of the diffusers in m

- Vz = Maximum velocity at the occupied zone regarding distance between diffusers and installation height in m/s

- Vk = Average effective velocity through the grill in m/s

- X0.25 = Throw length in m at an endvelocity Vt of 0,25m/s

- Ps = Static pressure loss given in Pa

- Lw(A) = Acoustic power in dB(A)

- The throw X0.25 is given at an end velocity of 0.25m/s for a smooth ceiling without any obstacles.

- The values are given for isothermal supply air. Throw distances for cooling conditions at -11K can be calculated by deviding the X0.25 values with factor 1.1. For heating purposes at Dt of +11K a multiplier of 1.1 should be applied to the given X0.25 value.

- In order to achieve a high comfort level, selections can be made according to the maximal velocity at the occupied zone Vz. These values are given at distances between diffusers B and installation heights H. Velocities Vz lower than, or equal to 0,25m/s at the occupied zone are advised.

- The pressure losses Ps are given for grilles without damper of with fully opened damper.

- The acoustic power Lw(A) are given for grilles without damper of with fully opened damper without room attenuation. Acoustic powers below 20dB(A) are mentioned as "<20" in the tables.

- For all special requirements, please contact our engineering office.

Placement instruction

|