PRODUCTS

EShop-number

Password

Welcome to CAIROX BELGIUM

HF R EC • Anti-acid centrifugal fans with EC motor

- Centrifugal fans

- EC motor

- up to 4.000 m³/h

Accessories

PVC • Flexible connectors AVM • Anti-vibration mounts DMD-C • Differential pressure transmitters with built-in controller KC (EC) • Motor protection covers ESCP • Potentiometers 0-10V

Datasheet

Manual / Operation manual HF R Centrifugal fans

Wiring / Diagram / Safety switch HF R Centrifugal fans

Wiring / Diagram / 0.37kW EBM Papst (discontinued)

Wiring / Diagram / 1.1kW EBM Papst (discontinued)

Wiring / Diagram / WEG-motor

Wiring / Diagram / ADDA motor

Certificates / CE

Other / Chemical resistance table

Anti-acid centrifugal fans with EC motor

Brand

- Hürner Luft- und Umwelttechnik

Application

- The fans are suitable for extraction of aggressive gasses

- They are particularly applicable for the extraction in:

- Laboratia

- Chemical and petrochemical industry

- Metal treatment industry

- Food and beverage industry

- Water treatment systems

Composition

- The casing is made of fire resistant polyethylene (PEs/PE-FR,RAL7036)

- The housing is fitted with a splinter guard and condensate drain at its deepest point

- The impeller is made of fire-resistant polypropylene (PPs/PP-FR) and is of the backward-curved blade type, statically and dynamically balanced according to Q 6.3 (VDI 2056)

- The impeller can be demounted without removing the housing

- Supply: 230Vac 1ph

- Protection: IP55

- Insulation class: F

- Integrated potentiometer for regulation of the motor

- Integrated safety switch

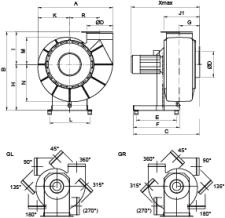

- Standard orientations: GR360, GL360, GR090 and GL090 - other orientations available on request

Accessories

- Flexible connections made of PVC, type PVC

- Set anti-vibration mounth, type AVM

- Protective cover for engine, type KC EC

- Potentiometers 0-10V, type ESCP010

- differential pressure regulators DMD-C

Options

- ATEX version in accordance with directive ATEX 94/9/CE

- Standard ATEX 3/-G (ATEX zone 2 inside / no ATEX zone outside)

- Terminal box for 0-10V control, price on request

Other available products

These HF R EC fans are just a few of the very wide range of HF-fans. For a selection and price, perfectly tailored to your project, please send your request to engineering@cairox.be.

Order example

- HF R EC 160-17D GR090

HF R: type of fan

EC: EC motor

160: diametre

17: type of impeller

D: direct driven

GR090: casing orientation

Requesting information. Please wait a moment...