PRODUCTEN

EShop-nummer

Wachtwoord

Welcome to CAIROX BELGIUM

CGW-M SG • Air/water heat pumps R32 Monobloc

- R-AQUA

- Air/water monoblock

- Outdoor unit

- R32

- 6 - 16 kW

Accessoires

TS-CLOUD • Wired WiFi room thermostat CASCADE • Accessories R-AQUA - Cascade BTE • Enameled buffer tanks MPRH • Anti-vibration high mounting blocks with rail TWV • Motorised 3-way zone valves with spring return AFP • Antifreeze valves AAS • Deaerators ADS • Magnetic dirt separators DPC • Differential pressure regulators WFS • Filling sets HEV • Expansion vessels for heating EVC • Expansion vessel consoles PAB • Protectors COD • Coding plugs SANI-EM • Domestic Hot Water Tanks SANI+ (2024) • Domestic Hot Water heater

Datasheet

Technical data / CGW-M SG 06 A1

Technical data / CGW-M SG 08 A1

Technical data / CGW-M SG 10 A1

Technical data / CGW-M SG 12 A1

Technical data / CGW-M SG 16 A1

Technical data / CGW-M SG 16 M1

Certificates / Energy label / CGW-M SG 06 A1.pdf

Certificates / Energy label / CGW-M SG 08 A1.pdf

Certificates / Energy label / CGW-M SG 10 A1.pdf

Certificates / Energy label / CGW-M SG 12 A1.pdf

Certificates / Energy label / CGW-M SG 16 A1.pdf

Certificates / Energy label / CGW-M SG 16 M1.pdf

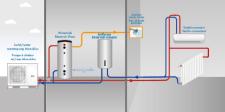

Air/water DC inverter-controlled monoblock heat pump with R32 refrigerant.

All hydraulic components such as a water pump, expansion vessel, pressure relief valve, back-up heater, etc., as well as the heat pump are combined in this monoblock. Thanks to the advanced heat pump technology, the energy from the outside air is absorbed and transferred to the water for home heating and cooling and domestic hot water. The intelligent regulation of the compressor and the expansion valve ensures precise and fast water temperature control, thus reducing energy consumption.Brand

- R-AQUA

Application

- Heating of new or existing houses

- Heating by means of radiators, convectors or floor, wall or ceiling heating

- Cooling by means of convectors, floor, wall or ceiling cooling

Production of domestic hot water, provided a hot water heater is installed

Composition

- High efficiency plate heat exchanger

- Energy-efficient circulation pump

Colour touch screen controller (wired)

- Expansion vessel (2 or 3 liters)

- Safety valve (3 bar)

- Electrical backup heater

- Water pressure sensor

Integrated outside temperature sensor

- DC inverter-controlled two-stage compressor with gas injection

- DC fan motor

- Gold Fin condenser

Refrigerant

- R32

Specifications

- Monobloc system

- 1 device for heating, cooling and domestic hot water

- Heating assured at outside temperatures down to -25°C

- Water temperature up to 55°C at outside temperatures down to -15°C

- A+++ at 35°C water temperature

- Bivalent setup

The heat pump will send a signal to an external heat source (eg gas boiler) depending on the outside temperature. This causes the heat pump stoped, and the second source present will provide the heating.

- Smart Grid ready

- Visual indication of energy consumption

- Standard equipped with WiFi

- Standard equipped with Modbus interface

- Easy installation

- EUROVENT EN 14511 and EN 14825 certification

- Keymark certification

Accessories

- Room Thermostat, type TS-CLOUD, TS-CLOUD RF (only suitable for heating)

- Cascade module, type CASCADE

- Buffer tank, type BTE 60, BTE 100

- Anti-vibration mounting blocks, type MPRH

- 3-way zone valve, type TWV

- Antifreeze valve, type AFP

Deaerator, type AAS

Magnetic dirt separator, type ADS

Differential pressure regulator, type DPC

Filling set, type WFS

Expansion vessel for heating, type HEV

Expansion vessel console, type EVC

Protector, type PAB

Coding plug for permanently disabling the cooling function, type COD-M-H

- Start-up is strongly recommended, type XSTARTUPJ

Applicable boiler

- Domestic hot water heater 200 liters, type SANI-EM 200

- Domestic hot water heater 300 liters, type SANI-EM 300, SANI+ 300

- Domestic hot water heater 500 liters, type SANI-EM 500, SANI+ 500

Informatie aanvragen. Even geduld a.u.b...