PRODUCTS

EShop-number

Password

Welcome to CAIROX BELGIUM

SF 24A-SR • Actuators with spring reset 20Nm modulating 0-10V

- Aeraulic

- Actuator 20 Nm

- Proportional

- With sping return

- Safety dampers

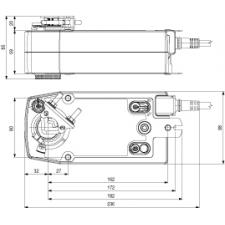

Servomotor with spring return for air volume safety dampers of up to 4 m² depending on the type of air valve and the pressure on the valves. Simple direct mounting on the damper axe with a universal spindle clamp, supplied with an anti-rotation strap to prevent the actuator from rotating

Brand

- Belimo

Application

- Safety dampers

Specifications

- Torque 20 Nm

- Nominal Voltage 24 V AC / DC

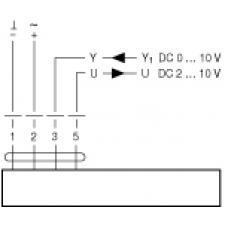

- Control: modulating standard control signal DC 0-10 V, position feedback DC 2-10 V. The measuring voltage U allows the damper position (0-100%) to be electrically indicated and serves as a follow-up control signal for other actuators

Accessoires

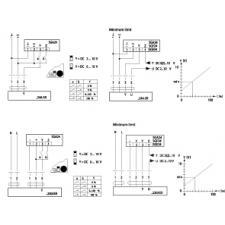

- Positioners, type SGA24 / SGF24

Requesting information. Please wait a moment...