PRODUCTEN

EShop-nummer

Wachtwoord

Welcome to CAIROX BELGIUM

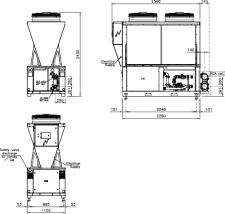

EVEREST R290 PAE WA Kp • Modular air/water heat pumps extra cooling/heating

|

|

- Heatpumps

- Air/water monoblock

- Emicon

- Modular units

- C 105 - 1050 kW / H 88,2 - 882 kW

- R290

- Optimized for cooling

Accessoires

PA-Kp (PAE GPE) • Rubber anti-vibration mounts for EVEREST 290 PM-Kp (PAE GPE) • Anti-vibration mounts with springs for EVEREST 290 KCA-Kp (PAE) • Water collector kits without insulation for EVEREST KCC-Kp (PAE) • Insulation for water collector kit KCA EVEREST KG5/KG10-Kp (PAE GPE) • Gateway framework kit for communication between up to 5 or 10 units in cascade KTT-Kp (PAE) • Endcaps and user connections for water collector KCA-Kp (PAE) EVEREST KP5/KP10-Kp (PAE GPE) • Electrical switch and connection boards for cascade up to 5 or 10 EVEREST 290 modules MG-Kp (PAE GPE) • Lifting hooks for EVEREST 290 KGR1-Kp (PAE GPE) • Gateway kits for one EVEREST module with Wi-Fi router KGR5-Kp (PAE GPE), KGR10-Kp (PAE GPE) • Gateway communication + Wi-Fi kits for EVEREST modules in cascade KGH5/KGH10-Kp (PAE GPE) • Gateway communication + Wi-Fi/ Hi-Web kits for EVEREST modules in cascade MT-Kp (PAE GPE) • Manometers in front panel of EVEREST 290 units A+V-Kp (PAE GPE) • Ammeters and Voltmeters EVEREST 290 KTA-Kp (PAE GPE) • Tablet interface kits for EVEREST 290 in combination with KGR or KGH kit ECP-Kp (PAE GPE) • Anticorrosive epoxy electro coating on air batteries of the EVEREST 290The EVEREST290 PAE WA Kp is a modular air/water heat pump with 2 pipes that is suitable for heating and cooling. Compared to the classic air/water heat pump PAE 881 Kp, this "WA" version has a plate exchanger and an air-side battery that have been optimized for cooling. The cooling capacity of this unit is no less than 59% higher than the standard PAE 881 Kp. Up to 10 of these modules can be placed in a cascade system. The monoblock unit is filled with the natural refrigerant propane (R290) and can reach outgoing water temperatures of up to 65°C.

The EVEREST290 is an appliance for heating and cooling that uses 2 scroll compressors with the same capacity. This ensures 2 power stages and low power consumption. Due to the specific construction, the appliance will switch to defrost mode less quickly and the defrost cycle is completed as efficiently as possible.

The unit maintains its high COP values even at negative outside temperatures.

Brand

- Emicon

Application

- Production of domestic hot water (up to 65°C)

- Heating or cooling in commercial applications

- Heating or cooling in industrial applications

Characteristics

Per module:

- PAE 881 WA Kp: Cooling capacity: 105 kW / Heating capacity: 88,2 kW

- In heating mode:

Outgoing water temperature up to 65°C at 0°C outdoor temperature

Outgoing water temperature up to 50°C at -20°C outdoor temperature

- In cooling mode with glycol:

Outgoing water temperature down to 0°C at -20°C outdoor temperature

Composition

- Modules of monoblock 2-pipe heat pumps that can be used stand-alone or in a cascade of maximum 10 units

- Reliable operation

- Maintenance-free propane leak detector

- Strong, compact, steel structure with powder coating RAL 7035

- Movable with hand pallet truck

- 2 EC fans

- 2 scroll compressors in tandem with crankcase heating in a soundproof casing

- Electronic expansion valve

- Insulated stainless steel plate exchanger with flow switch

- Copper/aluminium batteries mounted in V with innovative mini-channel technology and hydrophilic coating

- Winter regulation down to -20°C

- Phase monitor

- Plug-and-play hydraulic and electrical connections

Options

- Rubber anti-vibration mounts. Type PA-Kp (PAE GPE)

- Anti-vibration mounts with springs. Type PM-Kp (PAE GPE)

- Soundproofing jacket on compressors. Type Cl-Kp (PAE GPE)

- Ampere and voltmeter used to measure the electrical current absorbed and the electrical supply voltage of the unit. Type A+V-Kp (PAE GPE)

- Tablet interface kit in combination with KGR5/10 or KGH/10 kit in modular use. Type KTA-Kp (PAE GPE)

- Remote display. Type PQ-Kp (PAE GPE)

- Water collector kit without insulation (1 per unit). Type KCA-Kp (PAE)

- Insulation for water collector. Type KCC-Kp (PAE)

- Gateway framework kit for 2 to 5 units in modular use (1 in case of multiple units). Type KG5-Kp (PAE GPE)

- Gateway framework kit for 6 to 10 units in modular use (1 in case of multiple units). Type KG10-Kp (PAE GPE)

- Gateway kit for stand-alone unit with Hi-web and Wi-Fi router. Type KGH1-Kp (PAE GPE)

- Gateway board kit for 2 to 5 units in modular use with Hi-web and Wi-Fi router (1 case of multiple units). Type KGH5-Kp (PAE GPE)

- Gateway board kit for 6 to 10 units in modular use with Hi-web and Wi-Fi router (1 in case of multiple units). Type KGH10-Kp (PAE GPE)

- Gateway kit for stand-alone unit with Wi-Fi router. Type KGR1-Kp (PAE GPE)

- Gateway board kit for 2 to 5 units in modular use with Wi-Fi router (1 in case of multiple units). Type KGR5-Kp (PAE GPE)

- Gateway board kit for 6 to 10 units in modular use with Wi-Fi router (1 in case of multiple units). Type KGR10-Kp (PAE GPE)

- Display interface kit for monitoring leak detector. Type KLD-Kp (PAE GPE)

- Electrical switch and connection board for a kit up to 5 modules (connect main power here in case of cascade). Type KP5-Kp (PAE GPE)

- Electrical switch and connection board for a kit up to 10 modules (connect main power here in case of cascade). Type KP10-Kp (PAE GPE)

- Victaulic cap + socket kit/welded. Type KTT-Kp (PAE GPE)

- Lifting brackets securely attached to the frame to lift the unit with hooks and cables. Type MG-Kp (PAE GPE)

- Manometers in front panel. Type MT-Kp (PAE GPE)

- Anti-freeze tracing around the evaporator. Type RA-Kp (PAE)

- Double insulation around the evaporator. Type VB-Kp (PAE)

- Anti-freeze tracing around the internal hydraulic pipes. Type VH-Kp (PAE)

Versions

- PAE 881 WA Kp

- PAE 881 Kp

Order example

- PAE 881 WA Kp

Explanation

88

=

Nominal heating capacity (kW)

1 = Number of cooling circuits

WA = Plate exchanger optimised for cooling

Kp = Propane refrigerant

Informatie aanvragen. Even geduld a.u.b...